|

Page 9 - Welding

|

|

Welding has started, with the hull/keel joint in progress. In the upper left of the photo you can see the first chine, with the weld lengths marked out to guide the operator.

|

|

|

The hull/keel joint 50% welded on the inside. This stage has been reached after a few cycles of welding 2" lengths spread along the length of the keel and never coming back to weld in any area until the plate has fully cooled in that area. They are now ready to start filling in the gaps.

|

|

|

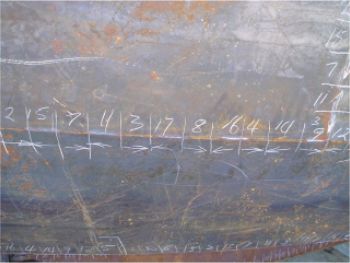

The outside of a chine marked for the welding to start. Note that the seam is marked for weld length and with a numerical welding sequence. The inside of the seam has already been welded with good penetration, as can be seen from the weld bead showing in the seam.

|

|

|

Same stage from another angle. The plates show no signs of distortion with the interior seams fully welded.

|

|

|