|

|

This series of photos was sent to us by Al Beyers, building his Didi 26 in British Columbia, Canada.

Timber keel foil construction starts with gluing the planks together to form a solid slab of timber. Here they have been glued and are held together with bar clamps until the glue has set.

|

|

|

Wood slab cleaned up, ready for shaping. Al has roughly marked the foil shape onto the end of the slab.

|

|

|

Rough shaping starts.

|

|

|

Cut-out in top of keel for lifting tackle.

|

|

|

Final shaping with a sander and checking shape with foil pattern. Note step at junction between foil and top of keel.

|

|

|

Glass covering of keel in progress. The glass is built up to 3mm thickness.

|

|

|

Same stage.

|

|

|

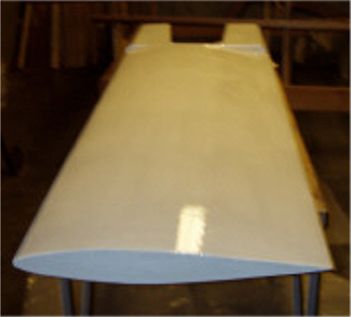

Completed keel.

|

|

|

Two halves of dropkeel casing, ready for fitting into hull structure. It has stop blocks bonded to the bottom edge to prevent the keel from dropping out of the bottom.

|

Back to Didi 26 Notes

|

Back to Didi 26 Notes

|